#26 2012-03-10 09:58:01

- formby

- Member

- From: Wiseacre

- Posts: 8359

Re: Australian Superfine Wool Growers - European Report 2010

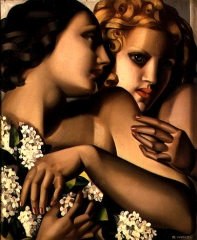

"Dressing, like painting, should have a residual stability, plus punctuation and surprise." - Richard Merkin

Souvent me Souvient

#27 2012-08-11 00:15:19

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

#28 2013-01-05 06:14:13

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

#29 2013-02-17 02:05:10

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

#30 2013-02-17 08:07:14

- xenon1

- Member

- Posts: 234

Re: Australian Superfine Wool Growers - European Report 2010

That's amazing. Perhaps someday super 250s suiting will be commonplace and as inexpensive as current 150s. I remember when 150s was a big deal.

#31 2013-02-17 18:47:43

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

#32 2013-02-17 20:55:51

- xenon1

- Member

- Posts: 234

Re: Australian Superfine Wool Growers - European Report 2010

So you are saying the Blakes are the exception to the rule?

TBH I am not sure why 75-80 mm staple is better than 110, when both have the same fineness. Wouldn't 110 make a stronger suiting all else being equal?

#33 2013-02-23 00:34:26

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

CSIRO reluctant to sell Geelong wool equipment cheaply to locals

By Sarina Locke Wednesday, 20/02/2013 ABC Rural http://www.abc.net.au/rural/news/content/201302/s3694394.htm

A group of wool producers is bidding to retain a piece of wool history in Australia.

They want to pay a nominal sum for the CSIRO's decommissioned worsted wool equipment in Geelong, Victoria, arguing it was bought by woolgrowers' taxes.

But the CSIRO isn't looking favourably at a cheap sale, saying it has new fibre research underway with Deakin University.

Peter Crisp, of Sustainable Wool in Australia Group (SWAG), says superfine wool processing needs to stay in Australia.

"We need to keep that transparent supply chain in Australia. Unfortunately AWI (Australian Wool Innovation) has forced processing overseas. That's wrong, we have to keep something in Australia for future generations."

Peter Crisp is a world renowned glass maker, who's made glass gifts for European Royal weddings from his workshop at Yass in NSW.

He's also a woolgrower, and now wants to process wool. With superfine woolgrowers like Barry Walker of the Mullion, he's formed the group SWAG, Sustainable Wool in Australia Group.

SWAG wants CSIRO to sell them, very cheaply, the worsted wool equipment lying disused in Geelong.

"Hundreds and hundreds and hundreds of millions of dollars have gone to the CSIRO in both wool tax and equally from the Federal Government.

"That worsted system is down at Belmont Geelong, and the site is being sold for a housing estate.

"It's the last worsted system in Australia. Once we lose that .... woolgrowers in Australia are forced to go offshore to process their wool.

"The equipment is Italian and German, 20 to 40 years old. SWAG plans to use it to scour or wash, card, spin and then dye wool.

"That would allow the production of a superfine wool fibre, which could be blended with alpaca, or silk, a boutique production line. "

The letter from Australian Wool Innovation says the "cost of maintaining the equipment and employment of qualified expertise will ultimately dwarf the purchase costs of this antiquated equipment".

"There is only a handful of fully vertical wool processing mills in the world today that tackle all these step which is what Mr Crisp proposes will be performed in his shearing shed. These vertical mills are $100 million facilities and process thousands of metres per day under climate controlled and sterile environments," says AWI.

Mr Crisp says AWI's own analysis reported to him that it could be viable.

AWI also points to the education being done by Deakin University's new Australian Future Fibres Innovation Centre (AAFIC) in Victoria.

AAFIC has a State and Federal grant for $70 million, and the CSIRO's deputy director of operations Mike Whelan says the CSIRO is collaborating on site with Deakin University.

"We're doing a lot of research on high performance fabrics these days. Examples of wool rich products for military, medical applications, advanced materials for sports and endurance."

The CSIRO and AWI exchanged a "sealed document", that remains confidential, but Mr Whelan says it relates to an asset swap from the late 1990s, including property at Ryde.

AWI says it dates back to 2001 and the AWI Annual Report in 2002-03 says says AWI received "$23.9 million from the CSIRO subsequent to the sale of the Prospect (in Sydney) property and the payment of $4 million to the Australian Wool Education Trust (AWET)".

Mr Whelan says the taxpayer has also funded CSIRO wool research.

Mr Crisp says AWI is not the sole custodian of woolgrowers' interests, that some boutique superfine wool processing needs to stay in Australia.

"We need to keep that transparent supply chain in Australia.

"Unfortunately AWI has forced processing overseas. That's wrong, we have to keep something in Australia for future generations."

Helen Cathles, of the Superfine Woolgrowers Association, has told the ABC there is no reliable top-making facility for superfine wool left in Australia, and this lack of capacity could lead to a deal with a leading fashion house, Icicle, in China, being lost.

#34 2013-02-28 03:12:24

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

Newcastle wool auctions to stop as volumes decline

January 29, 2013

Wool auctions at Newcastle in Australia will soon stop, ending a 70-year long tradition, as the firm that leases the selling facility at Newcastle has announced that the sales are no longer viable.

The drop in wool sales was cited as the main reason for the decision to stop wool auctions at Newcastle.

The last wool sale at Newcastle would take place in last week of February.

The Australian Wool Exchange (AWEX), which oversees wool sales at five selling centres, including the ones at Sydney, Melbourne and Fremantle, said the volume of wool sold at Newcastle has nosedived by 65 percent from 152,518 bales in 1999-2000 season to about 52,760 bales in 2011-12.

During the same period, the volume of wool offered across Australia declined by 45 percent from nearly 3.559 million bales to about 1.945 million bales, according to AWEX figures.

The closure of Newcastle wool sales would affect super-fine wool sales, as some producers who had a close liaison with buyers and brokers at Newcastle would now have to go to Sydney to sell their wool, which would add extra cost, according to analysts.

With the closure of Newcastle sales, focus would now shift to viability of wool auctions Fremantle, where the volume of wool auctioned is only a fraction of wool sold at Sydney and Melbourne auctions.

#35 2013-02-28 03:14:31

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

Short term pain, long term gain for wool industry

The National Council of Wool Selling Brokers of Australia

Chris Wilcox, the Executive Director of the NCWSBA, gave an invited presentation to the Nanjing Wool Market Conference in Sanya on 14th September with the theme of 'short term pain, long term gain'.

In the presentation Chris Wilcox noted the difficult conditions that wool textile mills in China and in other countries are facing currently given the economic stagnation in Europe, the slow recovery being seen in the USA and the slowdown in economic growth being seen in China itself. As well, he noted that wool production in Australia and around the world remains at very low levels, with no signs of increasing much in coming years.

The specific challenges being faced by China’s wool textile industry is illustrated in the trends in US imports of wool apparel over the past five years, both in terms of total imports and imports from China and Italy (two of the largest suppliers to the US). Total imports of wool clothing by the US have been below year earlier levels since the start of 2012. But, imports from Italy are above year earlier levels while imports from China have fallen. In other words, Italy is taking share from China. Imports from Italy are being supported, in part, by a decline in the Euro against the US$ and against the Chinese Yuan. As well, Italian wool textile mills are probably looking to other markets given the slowdown in sales within Europe.

Having said that, Chris also noted that current economic conditions are considerably better than they were in 2009 in the wake of the Global Financial Crisis. Chris Wilcox believes that this short term pain is likely to continue for the remainder of 2012, but leading economic indicators suggest a modest and slow improvement from the start of 2013. Looking further ahead, there are significant opportunities for wool given the continued increase in the world economy and world population.

There is strong growth predicted in both the world economy and in world population in coming years, which is causing growth in world fibre consumption. The strong growth in the world economy and population is a recipe for growth in world fibre consumption. While the volume of world wool production is unlikely to be able to match this growth rate, it means that wool prices could potentially rise if demand-building programs by Australian Wool Innovation and the International Wool Textile Organisation are successful

#36 2014-05-29 05:32:05

- fine

- Member

- Posts: 1

Re: Australian Superfine Wool Growers - European Report 2010

Hey my first comment on your site. ,I have been reading your blog for a while and thought I would completely pop in and drop a friendly note. . It is great stuff indeed.

#37 2014-05-29 06:39:41

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

Nice bump. Watching for spam.

#38 2014-07-09 03:58:39

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

#39 2014-07-09 03:59:41

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

Italian suit maker Zegna hopes for golden fleece after buying 60% of NSW sheep farm

Wednesday, 09 July 2014 2:39

Andrew Sadauskas

Italian suit maker Ermenegildo Zegna has made a major investment in a 2564 hectare sheep station near the town of Hillgrove in the New South Wales northern tablelands.

It’s welcome news for the Australian farming industry, with research earlier this year revealing most Australian family farms don’t earn enough to support the family on them.

The deal will see Zegna, the maker of suits favoured by former prime minister Paul Keating, purchase a 60% stake in the 175-year-old Achill sheep farm, which currently has 12,500 sheep in production.

The current owner, Charlie Coventry, will be appointed as chief executive of the venture, with wool produced at the property to be sold exclusively to Zegna, which exports its suits to 80 countries around the world.

In a statement, Ermenegildo Zegna Group chairman Paolo Zegna says entering the wool growing industry as a producer is a “great source of pride” for the company.

“The opportunity to better understand the daily work of the farmers, to share firsthand knowledge and to harmoniously participate in the development and promotion of this industry is quite exciting,” said Zegna.

“Our choice to acquire a breeding farm in Australia underscores the group’s faith in promoting a land and fibre which have played a crucial role in our history and our heritage,” he said.

The deal continues a long relationship between Zegna and the Australian wool industry, which launched an international advertising campaign promoting merino wool with Woolmark Australia in 2012.

Meanwhile since 1963, the Ermenegildo Zegna Extrafine Wool Trophy has been awarded annually to superfine merino wool producers.

Wool Producers Australia (WPA) president Geoff Fisken told SmartCompany the news is being welcomed by many in the industry.

“My first initial reaction was that this is good for the industry, that someone in the high-fashion industry is willing to put dollars into production – and I’m sure most of my board will share the same thoughts,” says Fisken.

“It’s great to see fashion people investing in the farm end of our industry,” he says.

SmartCompany attempted to contact Charlie Coventry but no comment was available prior to publication.

#40 2014-10-11 03:49:23

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

#41 2014-10-11 06:31:24

- woofboxer

- Devil's Ivy Advocate

- From: The Lost County of Middlesex

- Posts: 7959

Re: Australian Superfine Wool Growers - European Report 2010

^ The sleeves on that sweater look a bit long on you mate.

'I'm not that keen on the Average Look .......ever'.

John Simons

Achievements: banned from the Ivy Style FB Group

#42 2014-10-11 07:38:46

- fxh

- Big Down Under.

- From: Melbourne

- Posts: 6159

Re: Australian Superfine Wool Growers - European Report 2010

That's shooey